The Problem: Field Safety is Largely Reactive

The Shift: AI Makes Safety Predictive

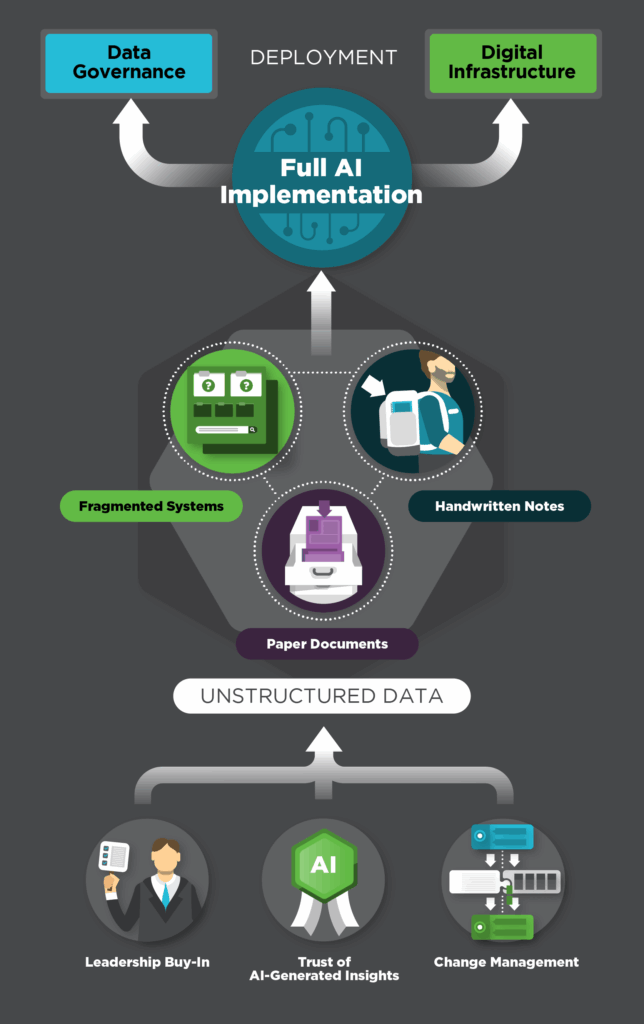

AI transforms this situation not only through improved pattern recognition but also by making unstructured data actionable. Traditional analytics can identify correlations in structured datasets. Still, the breakthrough with large language models (LLMs) lies in their ability to process the messy, real-world information where SIF precursors often reside, such as handwritten safety observations, free-text incident narratives, transcribed toolbox talks, and even voice recordings from the field. AI can identify when work involves high-energy sources such as heights, electricity, heavy equipment, or confined spaces and simultaneously lacks proper controls. It recognizes patterns like rushed work (e.g., overtime patterns or last-minute schedule changes) combined with high-energy tasks. This “widening of the aperture” allows leaders to shift from reactive incident management to proactive risk prevention where it matters most.

The Problem: Field Safety is Largely Reactive

The Shift: AI Makes Safety Predictive

AI transforms this situation not only through improved pattern recognition but also by making unstructured data actionable. Traditional analytics can identify correlations in structured datasets. Still, the breakthrough with large language models (LLMs) lies in their ability to process the messy, real-world information where SIF precursors often reside, such as handwritten safety observations, free-text incident narratives, transcribed toolbox talks, and even voice recordings from the field. AI can identify when work involves high-energy sources such as heights, electricity, heavy equipment, or confined spaces and simultaneously lacks proper controls. It recognizes patterns like rushed work (e.g., overtime patterns or last-minute schedule changes) combined with high-energy tasks. This “widening of the aperture” allows leaders to shift from reactive incident management to proactive risk prevention where it matters most.

For example, in one recent benchmarking study, we observed that if an employee's reported discomfort persisted beyond 72 hours,

%

Likelihood Of A Recordable Injury

For example, in one recent benchmarking study, we observed that if an employee's report discomfort persisted beyond 72 hours,

%

Likelihood Of A Recordable Injury

On the Frontlines: AI Tools That Change the Game

Beyond these pilots, AI is also enabling predictive safety management at the planning stage. Some utilities are deploying AI-driven risk assessment systems that score the risk level of each upcoming job in advance, allowing supervisors to decide whether to proceed, pause, or add extra controls before work begins. Likewise, modern EHS platforms augmented with AI can automatically scan incident logs and safety observations to pinpoint patterns of elevated risk—for instance, flagging a spike in near misses under certain conditions—so that crew leads and safety managers can address root causes earlier. These kinds of proactive, cross-data insights are analogous to emerging solutions in the industry (e.g., automated job hazard analysis and risk alert systems), illustrating how AI can change the game on the frontlines.

If You're Not Using AI, You’re Already Behind

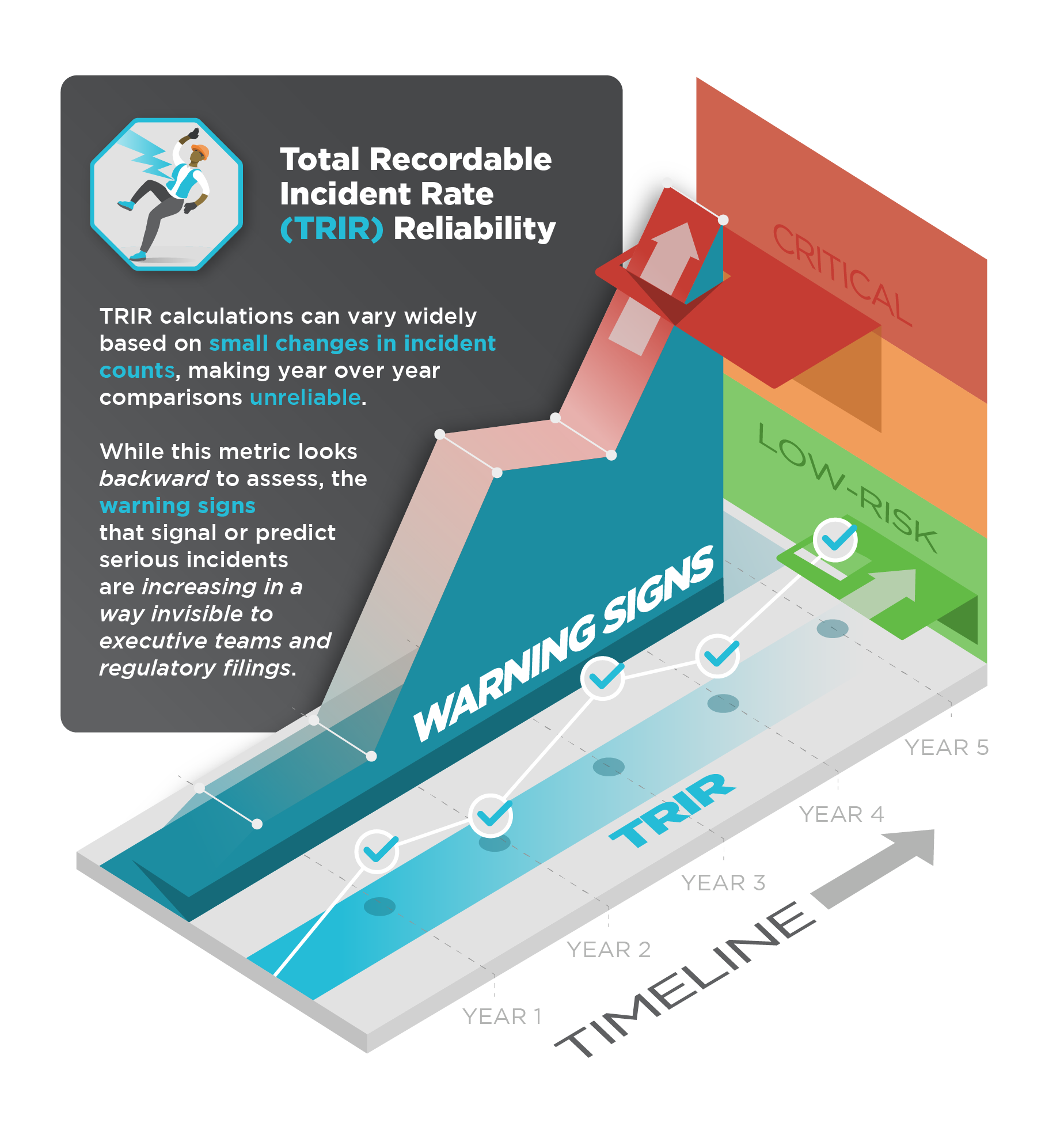

Lagging Indicators

| KPI | Description |

|---|---|

| TRIR | Total Recordable Incident Rate |

| Lost Time Incident Rate | Frequency of work-related injuries causing time off |

| Serious Injuries & Fatalities (SIFs) | Critical life-altering incidents |

| Recordables greater than 72hr Discomfort | Injuries reported after discomfort exceeds 72 hours |

| OSHA-Reportable Incidents | Regulatory safety reports filed |

| Days Away, Restricted, or Transferred (DART) | Work Disruption due to injury severity |

Leading Indicators

| KPI | Description |

|---|---|

| Near Misses Reported | Hazards reported before harm occurs |

| Ergonomic Flags Raised | Reports of physical strain or poor workstation setup |

| Safety Observations Submitted | Field-based hazard reports and safe behaviors |

| Field Coaching Sessions | Supervisor-led safety coaching conversations |

| Leadership Safety Walks | Management-led job site inspections and conversations |

| Job Briefs w/ AI Risk Alerts | Job plans augmented with predictive hazard prompts |

Lagging Indicators

| KPI | Description |

|---|---|

| TRIR | Total Recordable Incident Rate |

| Lost Time Incident Rate | Frequency of work-related injuries causing time off |

| Serious Injuries & Fatalities (SIFs) | Critical life-altering incidents |

| Recordables greater than 72hr Discomfort | Injuries reported after discomfort exceeds 72 hours |

| OSHA-Reportable Incidents | Regulatory safety reports filed |

| Days Away, Restricted, or Transferred (DART) | Work Disruption due to injury severity |

Leading Indicators

| KPI | Description |

|---|---|

| Near Misses Reported | Hazards reported before harm occurs |

| Ergonomic Flags Raised | Reports of physical strain or poor workstation setup |

| Safety Observations Submitted | Field-based hazard reports and safe behaviors |

| Field Coaching Sessions | Supervisor-led safety coaching conversations |

| Leadership Safety Walks | Management-led job site inspections and conversations |

| Job Briefs w/ AI Risk Alerts | Job plans augmented with predictive hazard prompts |

What ScottMadden Can Do

Phase 1: Discover and Prioritize

Phase 2: Pilot and Learn

Phase 3: Scale and Sustain

Phase 1: Discover and Prioritize

Phase 2: Pilot and Learn

Phase 3: Scale and Sustain

Alex Tylecote and Matthew Reed also contributed to this article.