Battery storage is rapidly expanding, and utilities are under pressure to move quickly while keeping reliability and safety at the forefront. We’ve witnessed the rapid pace of change—and the gaps that accompany it—in our work with utilities across the country. Fires in Arizona, California, and New York made it clear these aren’t one-off events. They serve as reminders that safety can’t be an afterthought.

Battery Energy Storage System (BESS) safety must be built into operations, not just bolted on during emergencies. That means combining the right planning, training, and coordination across the entire organization. Here’s where to start.

Three Things You Should Do Right Now

Three Things You Should Do Right Now

Assess Where You Stand

- Review your current safety plans for BESS and identify any gaps.

- Are SOPs, emergency procedures, and compliance checks currently and regularly practiced?

- Do you understand your exposure, operationally, financially, and reputationally?

Put a Safety Program in Place

- Governance and Alignment: Define a clear safety governance model and responsibilities from the C-suite to the site level.

- Cross-Functional Ownership: Align roles and activities across departments (safety, ops, planning, legal, etc.) to ensure ownership and accountability.

- Engagement and Preparedness: Include readiness planning with aligned protocols for first responders and authorities having jurisdiction.

- Performance Monitoring: Implement recurring internal audits, incident reviews, and regular reporting routines.

- Procedures and Documentation: Build and maintain clear safety procedures, documentation standards, and update cycles.

- Contractor Oversight: Establish contractor safety oversight, including onboarding, EHS requirements, and field verification.

- Operational Integration: Embed safety into outage planning, grid operations, and project reviews—not as an afterthought.

Run Real-World Training

- Use realistic simulation training (such as ScottMadden’s NXT GEN® to prepare for high-risk scenarios like thermal runaway, toxic gas, or fire.

- Train across the board: operators, plant staff, contractors, and local emergency teams.

- Consider regional mockups or shared training centers to keep costs manageable.

The Business Case for Safety

The Business Case for Safety

It doesn’t take a massive investment to build an effective BESS safety program. In fact, many utilities are investing less than $1 million and seeing substantial benefits:

- Preventing Major Events: Avoiding a single fire or explosion can save $10+ million in asset damage, downtime, and reputational loss.

- Improving Stakeholder Confidence: Proactive safety builds trust with regulators, local officials, and community members, making project approvals smoother and public perception stronger.

We’ve heard executives ask, “Can we afford to invest in safety right now?” The better question is: can you afford not to? A well-planned safety investment protects your people, assets, and reputation. The cost of prevention is almost always lower than the cost of recovery.

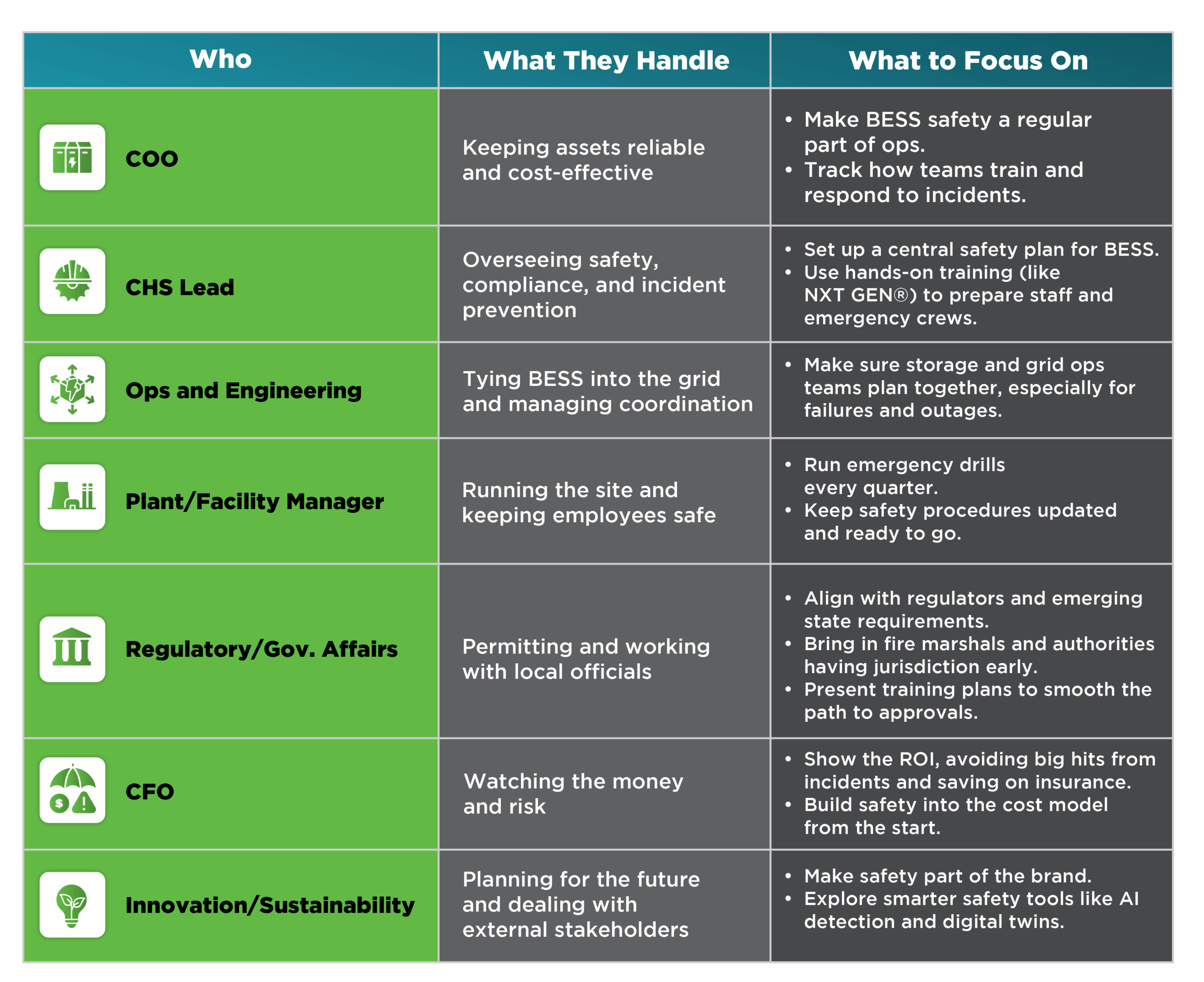

Safety Tips by Role

Safety Tips by Role

Battery storage is essential to the future grid, but getting it right means taking safety seriously, before regulators, insurers, or the public force the issue. We can help you get ahead of it. Let’s lead the charge, not clean up after the next one.