From "Why Modernize?" to "How Do We Transform?"

The U.S. nuclear industry is at a crossroads. After decades of underinvestment, mounting operations and maintenance (O&M) costs, and workforce challenges, the sector now faces tailwinds: stronger markets, rising demand, and bipartisan policy support for nuclear generation.

Yet progress remains fragmented. Utilities have tested AI tools, sensors, and mobile work packages, but those efforts rarely scale beyond a single site. The real challenge is not deploying new technology—it is operating model transformation. Nuclear must move from plant-centric improvements to fleet-wide integrated operations if it wants to deliver sustained results.

Why Transformation Has Been Hard

Three persistent challenges hold the industry back:

- Aging analog systems that are costly and incompatible with digital capabilities

- High operating costs that historically disadvantaged nuclear

- An eroding workforce pipeline, with attrition outpacing replacement

The bigger barrier is cultural and structural. Nuclear operators value proven approaches. That conservatism is essential for safety, but slows innovation. Past false starts in digital instrumentation and control (I&C) made the industry even more cautious. And capital is limited; modernization must compete with new generation, grid investments, and resiliency projects. Those realities reinforce incremental improvements instead of full transformation.

Lessons from Norway: Integrated Operations

The industry has seen this before. In the 2000s, Norwegian oil and gas operators were squeezed by costs, workforce challenges, and complex offshore assets. Their answer: Integrated Operations (IO)—centralized onshore support, standardized processes, and real-time fleet data. The results were undeniable: 20–30% O&M reductions and greater operational resilience.

Recognizing parallels, the U.S. Department of Energy’s Light Water Reactor Sustainability Program (LWRS) and ScottMadden created the Integrated Operations for Nuclear (ION) framework. ION adapts Norwegian IO to nuclear, providing a path to move from site-based silos to fleet-wide operations, supported by common data, processes, and governance.

ION: A Pathway for Nuclear

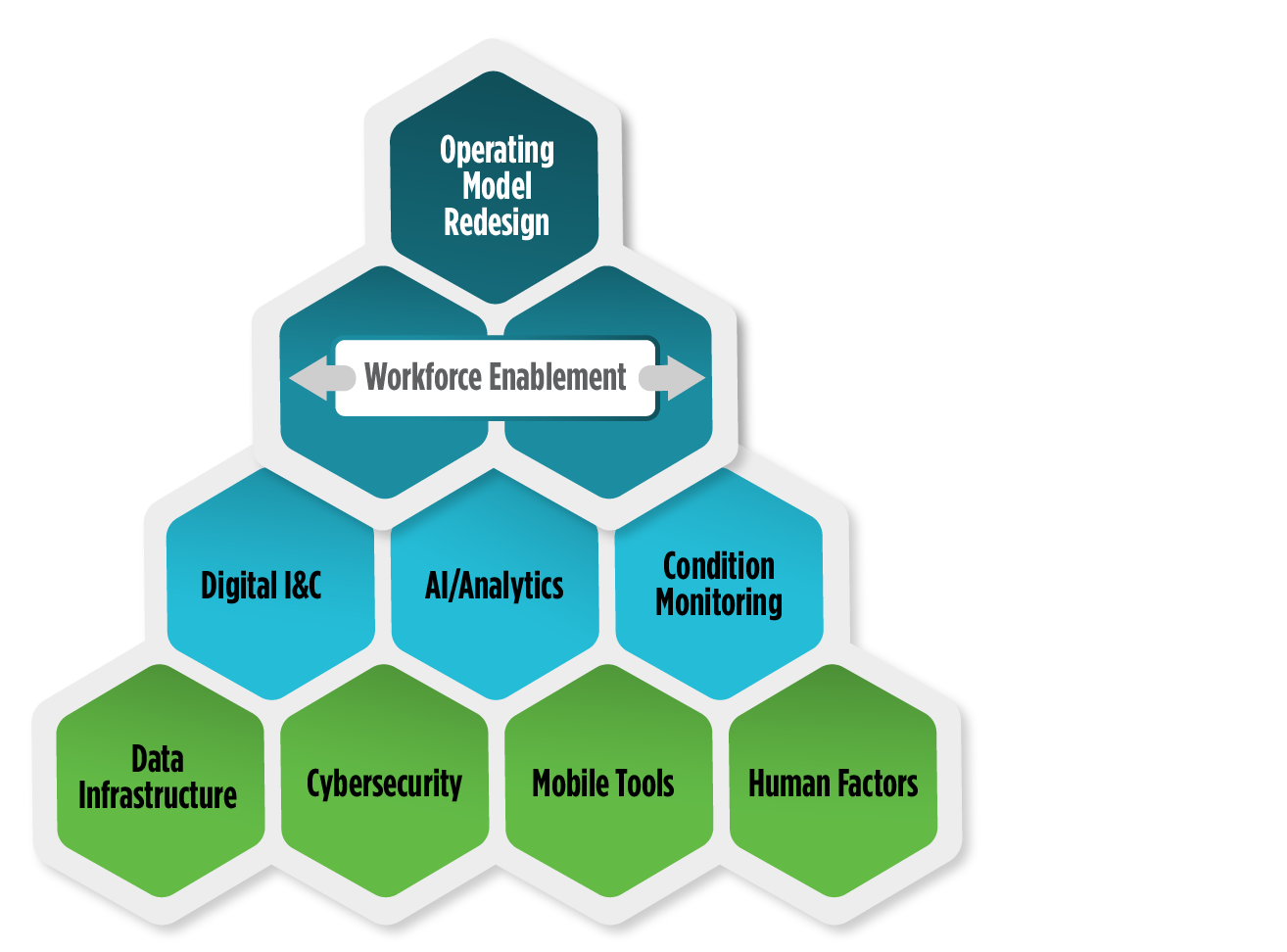

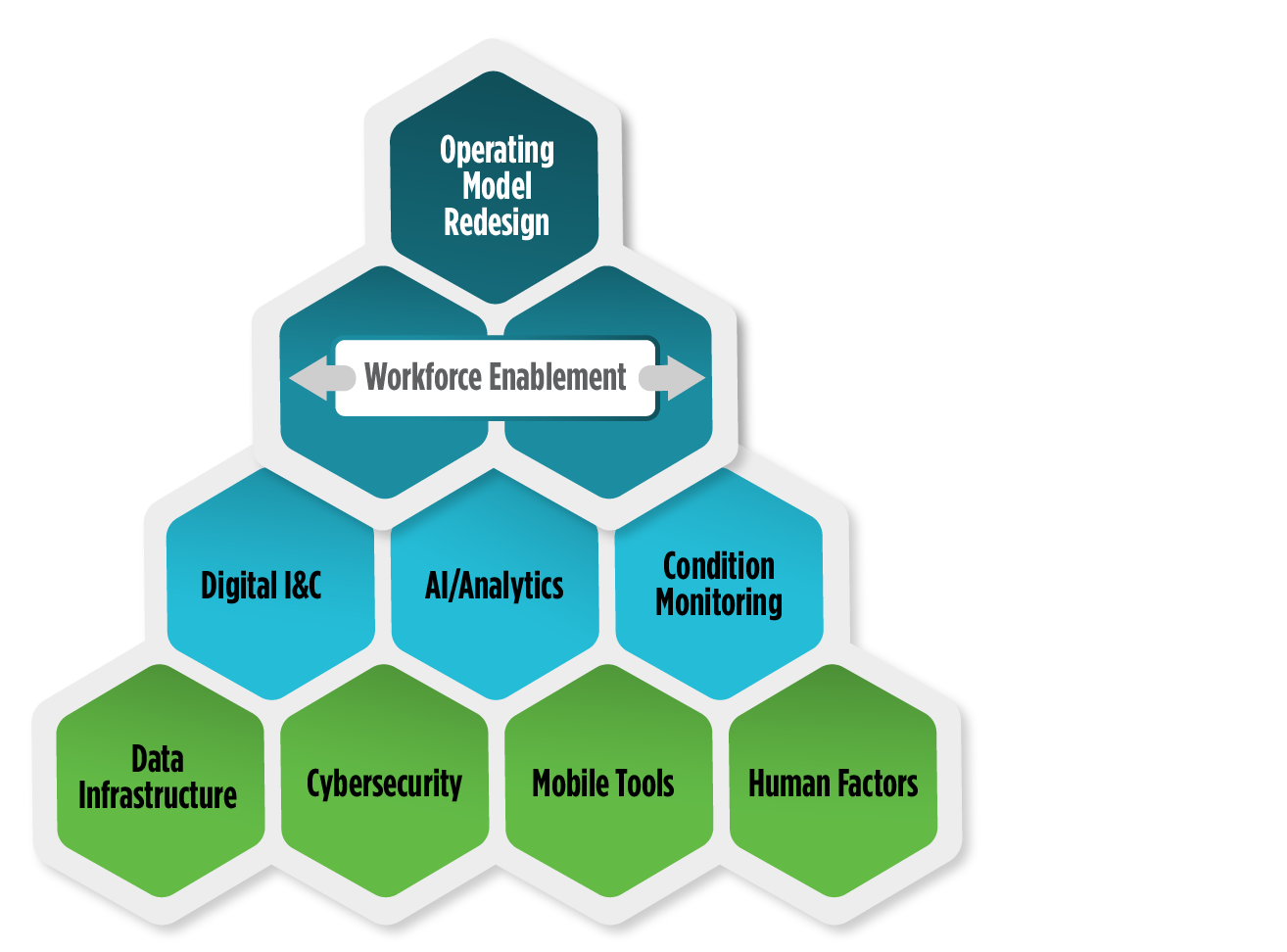

The ION framework integrates four domains that must advance together:

- Digital technologies such as I&C, mobile work, and advanced monitoring

- Data and analytics capabilities for better decision-making

- Workforce skills aligned to digital and AI-enabled operations

- Governance structures that enable scaling

Transformation only sticks when all four reinforce one another. That’s how operators move beyond pilots and into fleet-wide value.

Integrated Operating Model for Nuclear

Figure – Integrated Operating Model for Nuclear

ScottMadden's Role: From Framework to Field

ScottMadden has worked with INL and utilities to bring ION to life, with results published through LWRS papers here.

Our work has included:

- Developing modernization assessments that connect performance gaps with sequenced digital pathways

- Creating fleet-wide business cases to show how shared digital architectures reduce lifecycle costs and distribute risk

- Advising on capital bundling strategies that align modernization with uprates and other long-lived capital, improving regulatory alignment and approval prospects

We’ve also helped utilities confront a hard truth: modernization capital often competes directly with new builds, gas-fired generation, grid upgrades, and resiliency programs. Success depends on framing modernization not as an optional project, but as a strategic investment that secures nuclear’s role in the portfolio.

Modernization and Capacity Expansion: A Bundled Path

Modernization alone will not deliver uprates. But modernization and uprates can be bundled together as part of a larger capital strategy. Digital I&C upgrades, enhanced monitoring, and standardized processes do not create uprates by themselves–but they lay the technical and regulatory foundation that makes uprates more defensible.

Federal energy policy is increasingly clear: the U.S. wants more baseload capacity from the existing fleet. For operators, the opportunity lies in presenting modernization and uprates together–making the case for life extension, added capacity, and digital reliability as a single package. This is an emerging area that deserves attention from utilities, regulators, and policymakers alike.

From Framework to Implementation

The ION framework provides the foundation for nuclear fleet transformation. The next challenge is implementation. ScottMadden has developed comprehensive services across the full transformation lifecycle:

1. Transformation Planning and Business Case Development

2. AI and Digital Technology Deployment with Cybersecurity Integration

3. Organizational Alignment and Program Execution

1. Transformation Planning and Business Case Development

2. AI and Digital Technology Deployment with Cybersecurity Integration

3. Organizational Alignment and Program Execution

These services span from initial assessments through full implementation, addressing the technical, regulatory, and organizational dimensions of fleet-wide transformation.

Continue to Part II

For a detailed overview of how we translate ION principles into practical implementation, see:

Part II: Beyond Modernization – Building the Integrated Operating Model for Nuclear

Alex Tylecote also contributed to this article.